Boost Industrial Automation Efficiency with Rugged and Secure Bluetooth Sensor Networks

Contributed By DigiKey's North American Editors

2025-10-21

Internet of Things (IoT) sensor networks have proven to be a game-changer for industrial automation, renewable energy, and smart lighting systems by leveraging real-time data to advance efficiency and reduce downtime through predictive maintenance. However, as systems become equipped with an increasing number of wireless sensor nodes, designers are challenged to reliably scale these Industrial IoT (IIoT) networks in rugged environments while minimizing implementation and operational costs, addressing network overcrowding, and ensuring security.

This article provides an overview of the issues designers face when scaling IIoT networks. It then introduces Bluetooth Low Energy (BLE) modules and a development kit from Digi and shows how they can be used to address these issues quickly and efficiently.

The challenges of scaling wireless IIoT infrastructure

IIoT covers a wide range of applications where data acquisition is essential for improving efficiency and predictability. In smart lighting, for example, wireless sensors gather ambient light and occupancy data, adapting usage in real time to save energy and its associated costs.

Similarly, renewable energy applications use long-distance IoT sensor networks to monitor various energy sources, such as solar and wind. They monitor system status and performance, predicting issues and dynamically adjusting the grid supply.

As with other areas that use industrial automation, data acquired from moving parts is key to implementing predictive maintenance. Installing hundreds of wireless sensors throughout an industrial system provides granular data insights to optimize processes, reduce maintenance efforts, and lower running costs. But, as sensor networks scale, issues arise that can negatively impact performance, such as:

- Interference: Industrial environments are often burdened with high levels of electromagnetic interference (EMI) produced by motors, switched-mode power supplies, and arc welding apparatuses. This EMI can cause intermittence and reduced data rates that impede efficient data transmission.

- Network overcrowding: Operating multiple wireless devices in close proximity can saturate networks, resulting in higher latency and dropped connections that hinder real-time monitoring and increase power consumption.

- Security: Hacking is a significant concern for critical infrastructures, such as energy or logistics, so sensor networks must provide robust security. However, as the number of endpoints increases, so does the number of vulnerabilities.

Another challenge is integrating wireless sensors with standard industrial protocols. This integration can involve data reformatting and compression to reduce network traffic; however, these processes require on-device processing, which can quickly escalate in terms of cost and power as the number of sensors and protocols increases. Additionally, with more sensors in the field, maintenance efforts become increasingly complex, as they require unpredictable servicing, whether due to faults or simply changing batteries.

Bluetooth advantages for large-scale IIoT

Among the many IIoT wireless protocols, Bluetooth offers a powerful solution that addresses a range of issues as sensor networks expand. For example, it provides high immunity to interference by using adaptive frequency hopping (AFH). AFH breaks data into small packets that are transmitted over multiple frequencies and recombined on the receiving end. Any lost data packets are re-sent if reported missing, ensuring reliable communications and preventing long messages from being lost due to EMI.

To avoid network overcrowding, Bluetooth supports transmit power control relative to the receiver once a connection is established. This approach, combined with AFH, helps conserve power while minimizing EMI, allowing hundreds of wireless devices to operate in the same space. Additionally, Bluetooth mitigates security vulnerabilities through the use of strong encryption and resilient authentication protocols.

In IIoT deployments, large-scale Bluetooth sensor networks primarily communicate through gateways designed to pair with multiple devices. By building sensor nodes around Bluetooth, developers can provide seamless interoperability with smartphones and tablets, thereby streamlining setup and diagnostic work for enhanced maintenance efficiency.

However, for a wireless network to be suitable for IIoT, it must also reliably withstand harsh deployment conditions and be low-power, cost-effective, and easy to maintain.

Leveraging industrial-grade BLE modules for IIoT networks

The XBee 3 BLU BLE 5.4 modules and development kit from Digi provide designers with a rapid and straightforward path to deploying wireless IIoT networks. The modules meet reliability and power requirements through a combination of industrial-grade temperature tolerance from -40°C to +85°C and the use of idle and sleep operating modes. With a current draw of 7.5 milliamperes (mA) and 8 microamperes (µA), respectively, XBee 3 BLU devices can support long-term remote sensor installation in difficult-to-access locations, enabling valuable insights without requiring regular access for battery changes.

Other key features include:

- 2 megabits per second (Mbits/s) maximum data rate for detailed insights from complex machinery

- +8 decibels referenced to one milliwatt (dBm) maximum transmit power for high-fidelity communications at up to 15 meters (m) indoors or 300 m outdoors with a direct line of sight

- 13 digital I/Os and four 10-bit analog-to-digital converter (ADC) inputs for flexible integration with different equipment and sensor interfaces

- 1.71 to 3.8 volts supply for flexible power options

- Digi TrustFence Security for device and network protection, including secure boot, protected hardware ports, and device authentication

- Advanced MicroPython programmability for rapid development of on-device data processing and decision-making systems

- Complete regulatory approvals for North America (FCC, IC) and Europe (ETSI)

Examining the XBee 3 BLU module options

Digi offers several XBee 3 BLU models to suit different design needs and sensor form factors. The XB3-24B5UM-J (Figure 1) is a surface-mount solution featuring a U.FL connector for external antenna connectivity. Similar models are available with chip and RF pad antenna options.

Figure 1: The XB3-24B5UM-J offers a low-profile solution for powerful BLE communications in industrial environments. (Image source: Digi)

Figure 1: The XB3-24B5UM-J offers a low-profile solution for powerful BLE communications in industrial environments. (Image source: Digi)

Measuring 13 mm × 19 mm × 2 millimeters (mm), this form factor is well-suited for low-profile sensors designed for highly integrated industrial environments, such as smart lighting fixtures. Direct soldering onto printed circuit boards (pc boards) can also increase sensor durability and reliability in harsh environments, such as factory assembly lines.

Alternatively, the XB3-24B5PT-J (Figure 2) is a through-hole variant of the XBee 3 BLU module. This form factor features a pc board trace antenna, with a U.FL option.

Figure 2: The XB3-24B5PT-J is a through-hole module that can be easily swapped with alternative XBee modules serving different wireless protocols for greater design flexibility. (Image source: Digi)

Figure 2: The XB3-24B5PT-J is a through-hole module that can be easily swapped with alternative XBee modules serving different wireless protocols for greater design flexibility. (Image source: Digi)

Despite its larger footprint of 24.38 mm × 27.61 mm, this through-hole form factor offers an advantage for developers designing IoT sensors for various other applications. By installing headers on a common carrier board, the same sensor design can serve different wireless protocols by swapping this module with another from the broader XBee ecosystem. This reduces design efforts for developers and adds flexibility to IIoT infrastructure.

Streamline BLE-based IIoT system development with the XBee development kit

To accelerate a project build, designers can begin with the XK3-B5M-WBT XBee 3 BLU development kit (Figure 3). It features an XBIB interface board and key peripherals to support immediate wireless sensor prototyping, including:

- current monitoring header

- temperature/humidity sensor

- Grove connector for third-party sensors

- programmable user buttons

- USB or battery power options

Figure 3: The XK3-B5M-WBT development kit provides an ideal starting point for designing IIoT sensor networks based on BLE. (Image source: Digi)

Figure 3: The XK3-B5M-WBT development kit provides an ideal starting point for designing IIoT sensor networks based on BLE. (Image source: Digi)

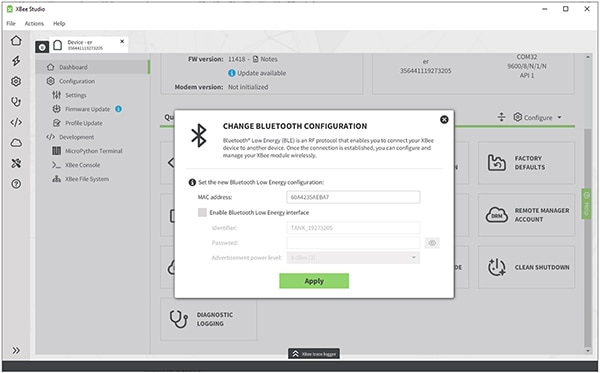

The kit also provides access to Digi XBee Studio. This free, multi-platform application enables faster time to market through a wide range of development tools, including a complete BLE 5.4 software stack, as well as additional documentation and examples. The simple graphical user interface (GUI) (Figure 4) provides easy, step-by-step configuration and management of multiple XBee devices simultaneously.

Figure 4: XBee Studio is a comprehensive software environment designed to accelerate the development and testing of XBee IIoT nodes. (Image source: Digi)

Figure 4: XBee Studio is a comprehensive software environment designed to accelerate the development and testing of XBee IIoT nodes. (Image source: Digi)

Alongside XBee Studio, the Digi XBee Mobile App enables local configuration and over-the-air (OTA) firmware updates for hands-on troubleshooting in the field. The Digi Mobile SDK supports app development for iOS and Android systems, enabling developers to streamline end-user interactions with XBee-based sensor networks, resulting in easier and more efficient device management.

Conclusion

When designing large-scale IIoT sensor networks for data acquisition, developers can encounter many challenges related to interference, security, integration, and maintenance. The Digi XBee 3 BLU modules provide a low-power, industrial-grade BLE solution that offers built-in edge computing capabilities to streamline data management. With flexible integration options and full-featured development resources, the modules form a reliable platform upon which to build and scale advanced sensor network systems quickly and efficiently.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.